“Thanks for all of your support over the years, you have been consistently my easiest supplier to work with”

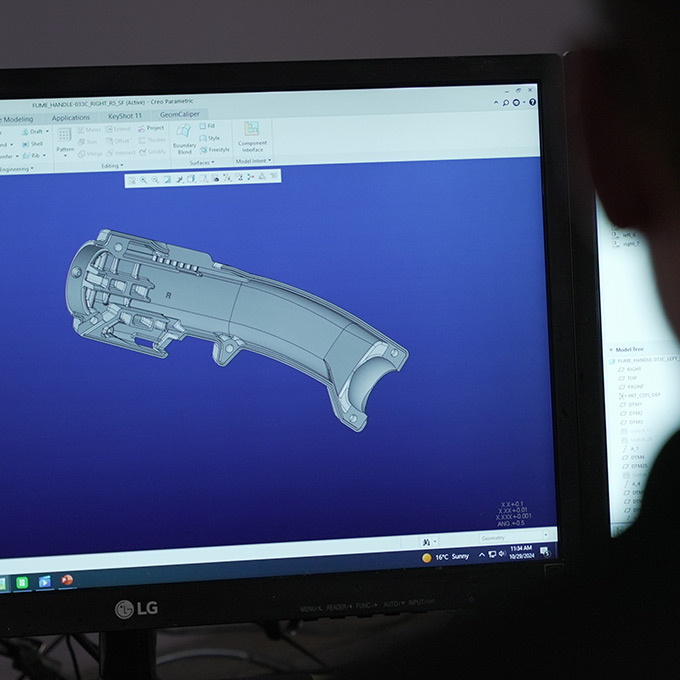

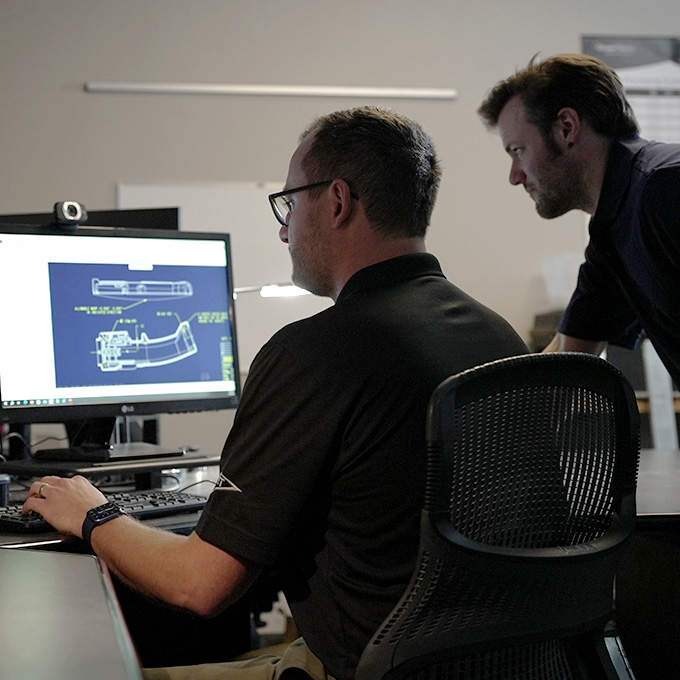

From initial concept to final product, our design and development process is centered around collaboration and precision, and our iterative approach allows for continuous refinement and optimization throughout the development process.

Our engineers guide you through the process of choosing the most suitable plastics based on your application’s requirements. This thorough approach helps us deliver reliable and high-quality products.

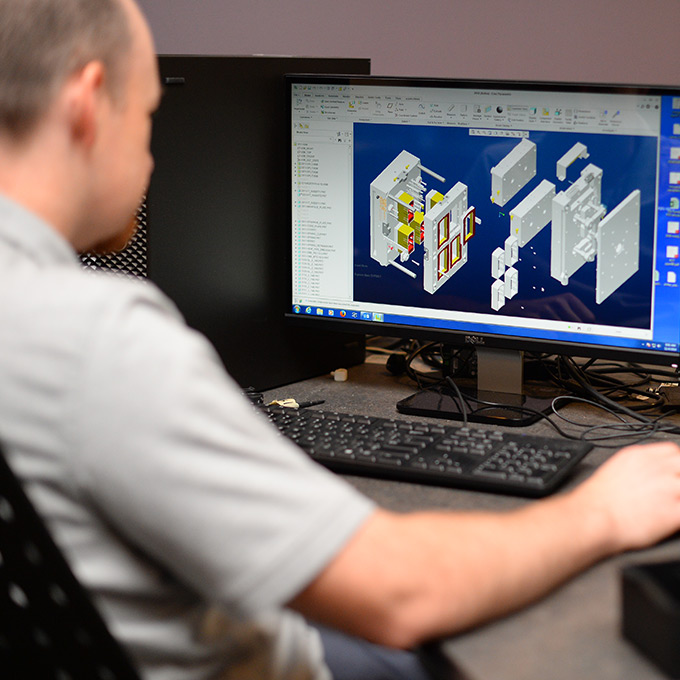

Efficiency and quality in manufacturing are key to delivering consistent results. Our engineering team is involved in optimizing product designs, tooling, and manufacturing processes to enhance productivity and reduce costs. Our focus on process improvement helps us maintain high standards of quality while meeting your project deadlines.

Our engineering team oversees every aspect of your project, from planning and design to production and delivery. We use proven project management methodologies and a focus on clear communication to ensure that timelines, budgets, and quality standards are met.

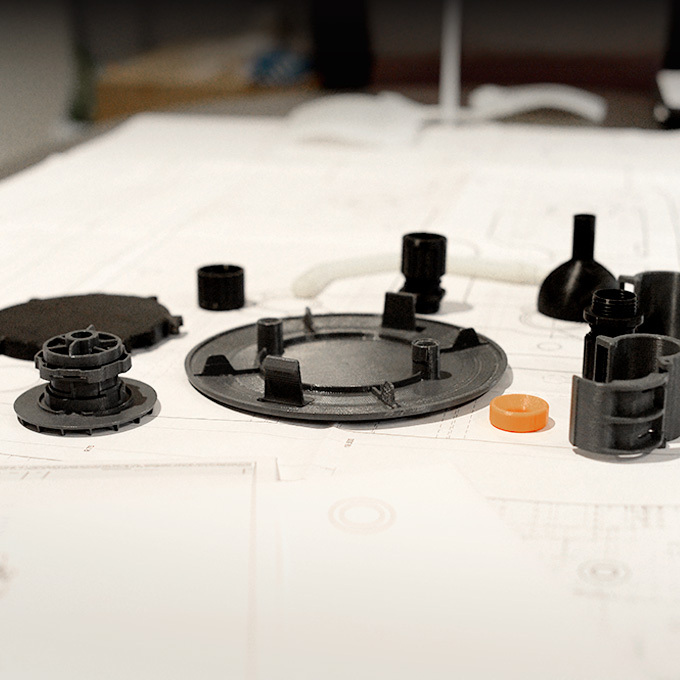

We use multiple rapid prototyping technologies to accelerate the product development process, including FDM, SLS, Multi Jet Fusion, and others. With 3D printing there is no need for tooling, as the prototypes are built layer by layer directly from a digital design. This eliminates the upfront costs associated with tooling, allowing for rapid design iteration and cost-effective product development.

Our team of plastics specialists will help transform your ideas into reality. Typical topics discussed during the engineering consultation phase include:

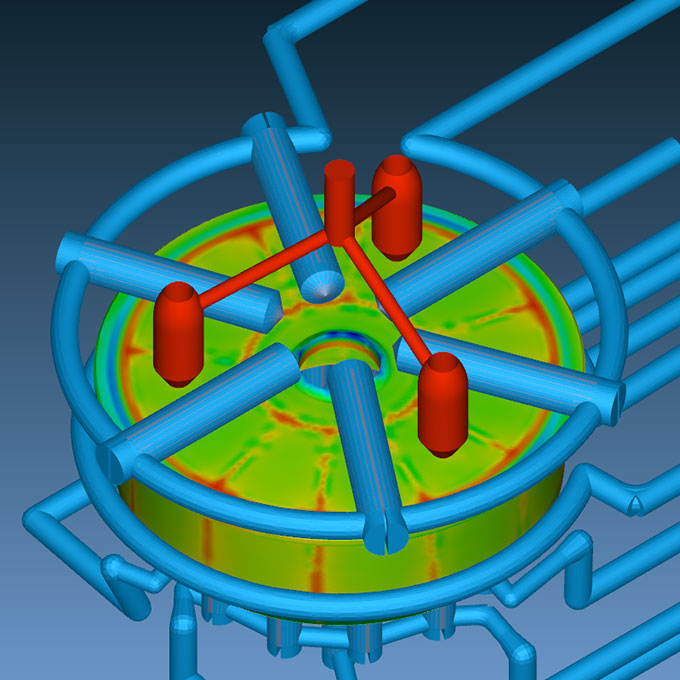

Melet uses Moldex3D software to simulate the flow of molten plastic during the injection molding process. Moldflow simulation allows us to evaluate key aspects of part and tooling design, including:

This virtual testing helps prevent common molding issues and supports faster, more accurate mold design iterations.

We’re here to help! Reach out to our team for personalized support and start your journey with Melet Plastics.