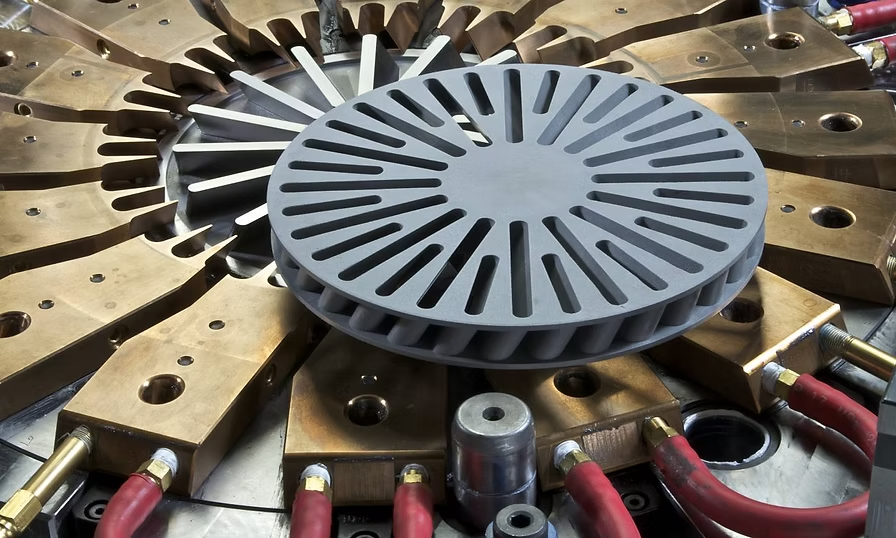

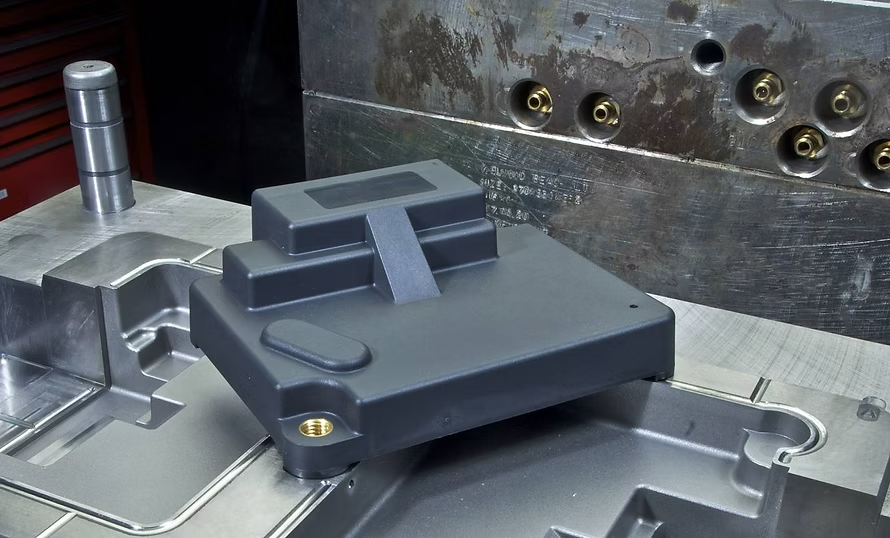

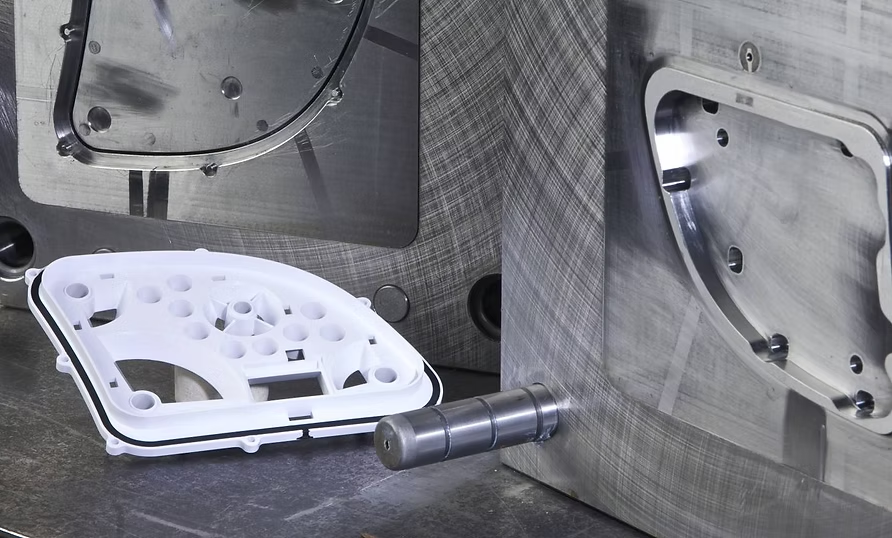

Overmolded Gaskets

Our customer required an injection molded hard body “eggcrate” component with integrated overmolded gaskets using a softer material on both sides of the part. Because the eggcrate was to be used in an industrial application, the gaskets needed to ensure a complete seal of the display enclosure from the environment.