“Thanks for all of your support over the years, you have been consistently my easiest supplier to work with”

Yes, we can offer the combined benefits of injection molding and UHMWPE!

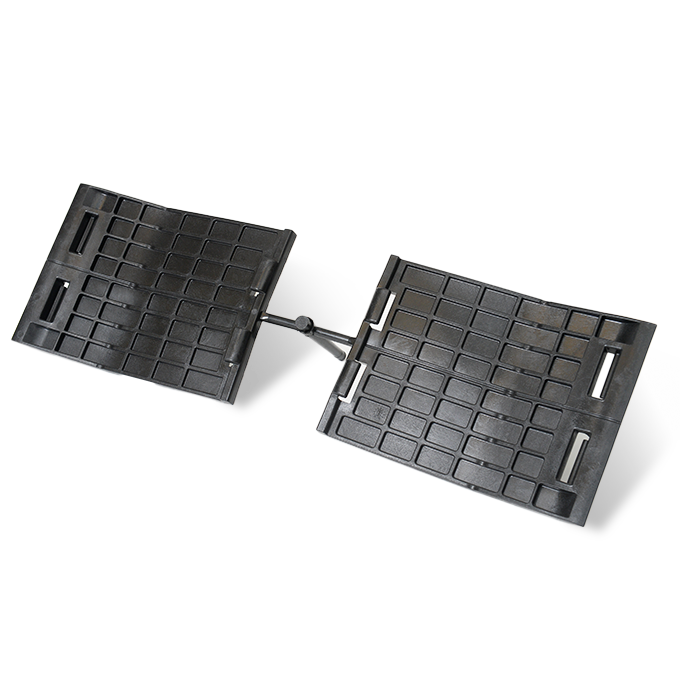

Melet has developed a proprietary process and material for injection molding of Ultra-High Molecular Weight Polyethylene (UHMWPE). This allows us to provide unparalleled benefits in an injection molded UHMWPE part.

Advantages of Melet’s proprietary UHMWPE:

Melet Plastics offers the unique capability to injection mold UHMWPE thanks to our state-of-the-art factory, plastics expertise, and years of R&D to develop our proprietary process and material.

Our team of engineers and technical sales professionals will help develop the right UHMWPE solution for your specific application. Leverage our secrets to achieve success with your application.

Contact us now to begin developing your custom engineered solution.

Injection-moldable UHMWPE resin is an extremely versatile material and well suited to many industrial applications. The injection molding process allows for reduced time and costs in comparison to more traditional machined UHMWPE production—benefits we pass on to you. Injection molding also allows for more advanced designs and geometry, including over-molding on other materials, bonding with elastomers, and insert molding of threaded metal inserts.

We’re here to help! Reach out to our team for personalized support and start your journey with Melet Plastics.