“Thanks for all of your support over the years, you have been consistently my easiest supplier to work with”

Streamline your supply chain: improve cost, lead time, quality, and service with Melet Plastics’ expert tool transfer solutions.

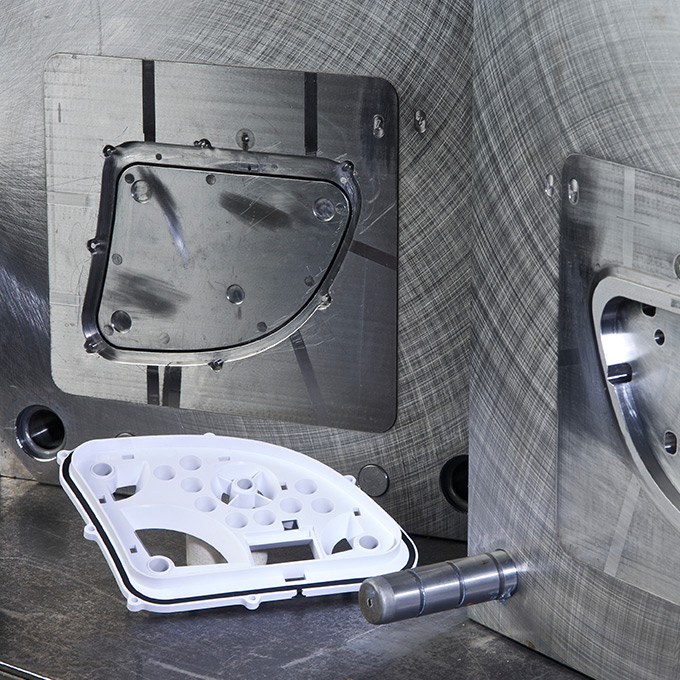

Melet’s tool transfer services are designed to help you seamlessly relocate your existing molds and tooling from another facility to our factory — ensuring minimal downtime, low risk, and maximum productivity.

With years of experience in the injection molding industry, our team of skilled engineers provides comprehensive support at every stage, from initial assessment to final setup, testing, and qualification in our factory. We handle scheduling and logistics, safety stock planning, mold inspection, mold refurbishment, and installation, allowing you to focus on what you do best—running your business.

We begin with a thorough assessment of your current tooling setup, manufacturing process, and transfer needs. Our experts will work with you to develop a detailed plan that ensures a smooth transition. By reviewing sample parts from recent production and looking at your history of non-conformances, we can make recommendations to improve product quality as part of the transfer.

We develop a plan and schedule to ensure that all required steps in the process are accounted for and there are no surprises. The schedule allows you to build up an appropriate level of safety stock to span the transfer process, minimizing your risk. Time for mold shipping, raw material sourcing, mold repairs and preparation, mold trials, qualification, and approval is all factored in.

Our in-house toolroom capability allows us to inspect your mold upon arrival and perform any necessary modifications, repairs, and setup. Once the tool is ready to trial, our process engineering team develops a robust injection molding process to ensure we can repeatably meet your specifications for the long term.

Parts are inspected by our QA team and a full PPAP report is submitted. Once approval is received, the tooling is released for production.

Account Manager - Responsible for coordinating, integrating and facilitating efficient communication among the group.

Project Leader - Leads and coordinates all phases of the project

Toolroom Manager - Accountable for evaluating molds and creating improvement recommendations to ensure the mold runs well in our factory.

Quality Representative - Responsible for evaluating part prints, gauges and fixtures, and dimensional inspections, as well as creating quality sheet work instructions.

Process Engineering Manager - Responsible for ensuring each mold has a robust process window in the new environment. All transferred molds must be qualified in the presses that will be used for future runs.

We’re here to help! Reach out to our team for personalized support and start your journey with Melet Plastics.