“Thanks for all of your support over the years, you have been consistently my easiest supplier to work with”

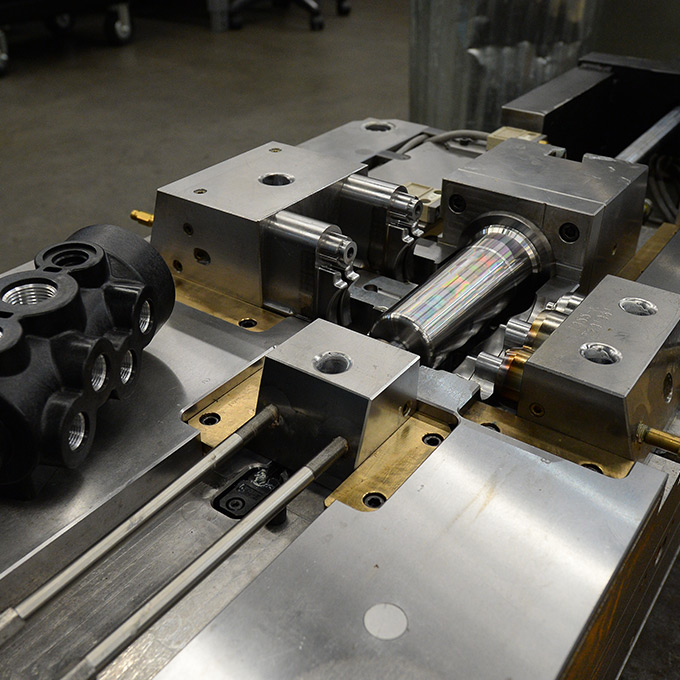

Unlike some parts manufacturers that use a third-party supplier to create their tools, Melet maintains a full mold manufacturing facility in-house. Supported by advanced state-of-the-art machines and software, our toolroom specializes in high-tolerance, high-complexity tools that need to be produced to exacting standards. We use PTC Creo CAD software to design our molds and they are optimized via Moldex3D moldflow simulation software.

Our in-house toolroom features the following equipment:

For projects with budget/timeline constraints, Melet has developed strong relationships with global mold suppliers who build high-quality injection molds to our specification.

Tooling amortization is available for qualified projects.

Our internal tooling capability allows us to perform insert changes and tool maintenance with ease, ensuring that all molds are kept in excellent condition and ready to meet the needs of production quickly.

We’re here to help! Reach out to our team for personalized support and start your journey with Melet Plastics.