“Thanks for all of your support over the years, you have been consistently my easiest supplier to work with”

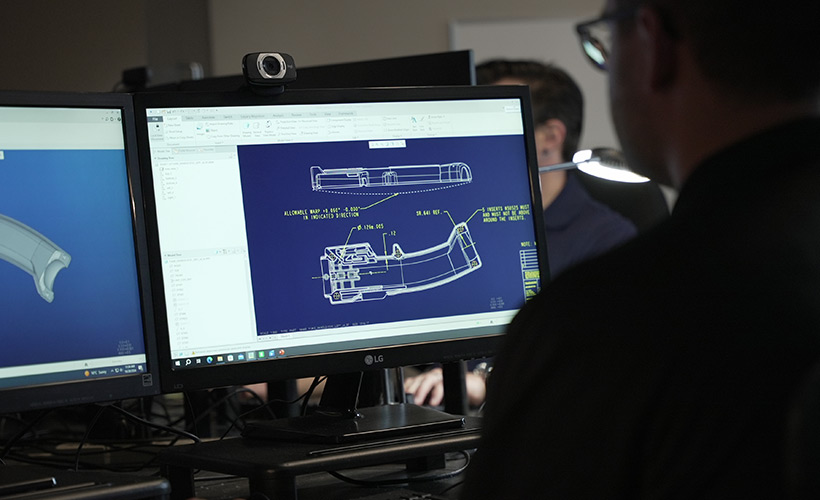

We believe in collaboration from the very beginning. Our design and prototyping services help bring your ideas to life, allowing you to visualize your product before production. We work closely with you to refine designs and make necessary adjustments, ensuring a seamless transition from concept to finished product.

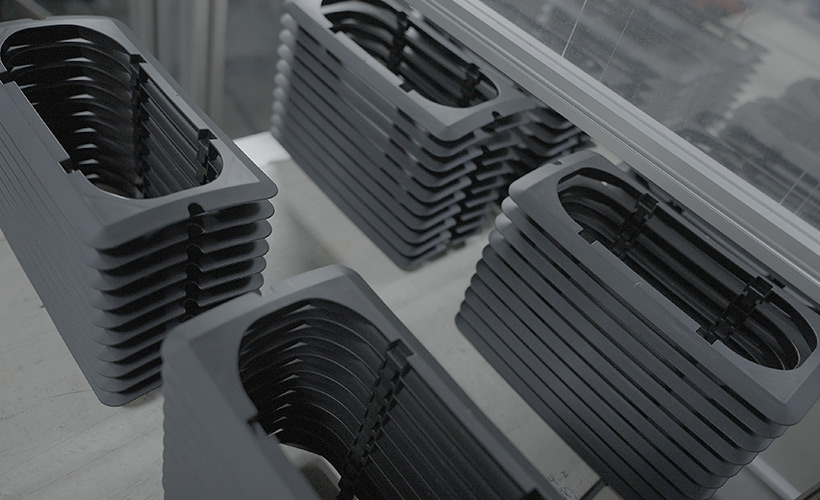

Melet Plastics’ proprietary process and material for injection molding of Ultra-High Molecular Weight Polyethylene (UHMWPE) allows us to provide unparalleled benefits in an injection molded UHMWPE part.

Our in-house custom tooling manufacturing allows us to design and manufacture molds that are specifically tailored to your product requirements, ensuring efficiency and precision in production.

Our advanced injection molding services produce complex plastic parts with high precision and efficiency. Whether you need small prototypes or large-scale production runs, our team ensures consistency and quality at every stage of the process.

We offer a range of secondary operations to enhance the functionality and aesthetics of your products, including assembly, pad printing, ultrasonic welding, hot stamping, and CNC machining.

If you’re looking to streamline your supply chain, our tool transfer services provide a seamless solution. We specialize in transferring existing molds and tooling from other facilities, ensuring they integrate swiftly and smoothly into our production line while maintaining all specifications and quality standards.

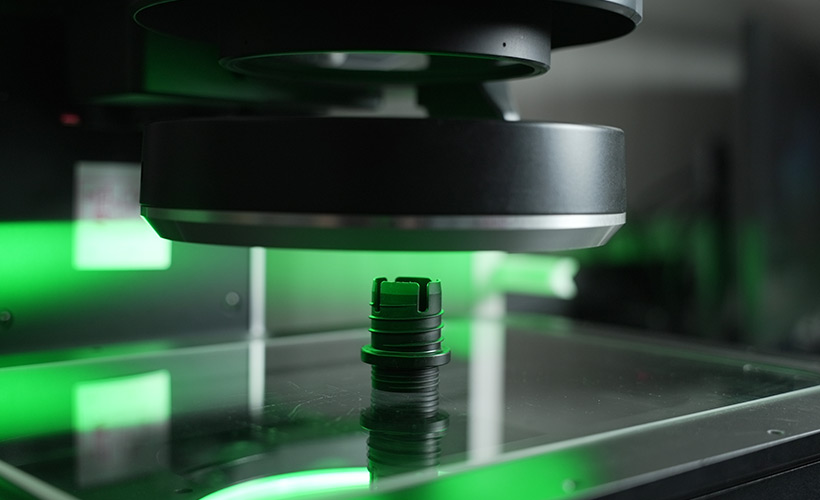

At Melet Plastics, quality is built into every step of our process. As an ISO 9001-certified manufacturer, we follow strict quality standards to ensure consistent, high-performance parts for every customer. From material verification to final inspection, our QA team uses advanced measurement tools to meet your exact specifications—every time.

We’re here to help! Reach out to our team for personalized support and start your journey with Melet Plastics.