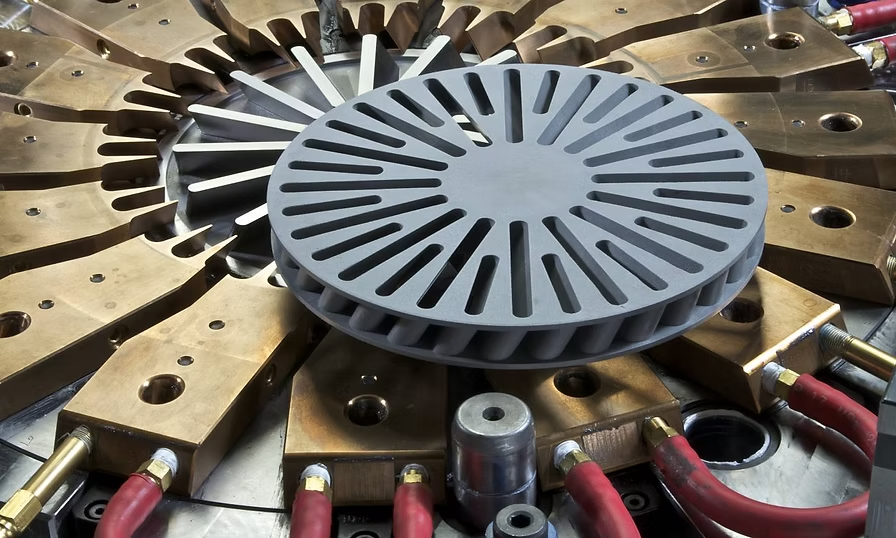

This customer required a plastic diffuser for use in its floor ventilation system. Of somewhat complicated design, the diffuser presented several engineering challenges including heavy point load requirements, flame retardant specifications and multiple undercut features at extreme angles.

Working from the diffuser’s existing design, Melet’s engineering team fine-tuned the part for injection molding, ensuring that it maintained it’s specifications for strength. We then identified the best specialty engineering resin for the client’s flammability and mechanical specifications.

Design of the tool provided the biggest challenge, as it required no less than 16 external slide actions and 32 internal multi-angle lifter mechanisms for completion. The mold assembly itself was manufactured entirely in Melet’s toolroom relying heavily on our advanced CNC wire EDM technology capabilities.

We’re here to help! Reach out to our team for personalized support and start your journey with Melet Plastics.